Our first commercial plant builds on years of technical expertise developed at lab scale and during our demonstration program. This program, supported by 9M€ European Funding (Sylfeed), consisted in scaling-up our process and confirming our product performances in our selected markets. From 2017 to 2021, with the support of our partners, we ran extensive fermentation trials to go from litre scale to multi cubic meter scale and fine-tune our process parameters to deliver the best product performance.

In parallel, since 2017, in vivo trials were performed in partnership with renowned universities (INRAE, Kansas State, Texas A&M,…). We’ve demonstrated SylPro’s superior performance for petfood, aquaculture, and swine; and validated Yusto’s inclusion in human food prototypes.

Production

Industrial Deployment

Arbiom is focused on rolling-out its industrial project to contribute to a more sustainable food system. Our first industrial plant, located in France, will deliver 10,000 tons/ year of high quality and sustainable protein ingredients and create local jobs in a strategic sector.

In 2022 Arbiom secured 12m€ funding from France Relance to make this major industrial project a reality

Large scale operations are now executed on demand to supply samples for customers and partners.

Contact us for more information and samples.

Contact usTechnology

Arbiom harnesses the power of fermentation to address the challenges of feeding the world in a sustainable and healthy way.

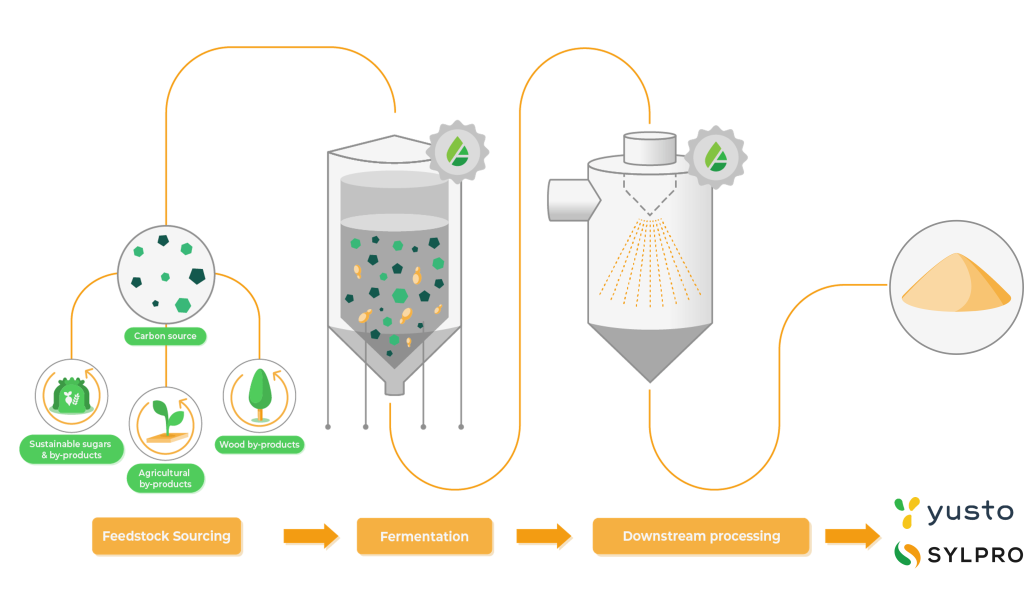

We produce sustainable, nutritional protein ingredients for feed and food to meet global nutritional needs thanks to our integrated technology platform. SylPro for feed & Yusto for food are both dried, inactive yeasts, produced through a three-stage process comprised of a natural fermentation followed by liquid/solid separation prior to drying. One of Arbiom’s strengths relies in our proprietary strain which has the unique ability to convert a wide range of carbon sources, ranging from traditional agricultural sources up to by-products and wood residues, with no compromise on quality and performance of the end-product.